Hitachi Primaide HPLC

- Simple design and front-access layout, makes maintenance easy.

- Built according to strict specifications to meet such stringent requirements. Can be applied to an even wider range of applications by employing optional units, such as a sophisticated DAD (Diode Array Detector) and an autosampler cooling unit.

- Hitachi's strict production quality standards ensures both high performance and endurance.

Dionamix HPLC

Dionamix L-3000 HPLC Systems were designed in accordance with UHPLC standard, with pressure limit 9,000 psi, that is the highest pressure range compared to similar HPLC systems.

It can be widely used in the fields of pharmaceutical, biochemical, environmental, food safety, petrochemical engineering, agriculturaland etc.

Surwit STI 501 Binary HPLC

- Flow: 0.001-10.000 ml/min

- Max Pressure: 6000 psi

- Wavelength Range 190-700 nm

- Flow pool volume: 10μL

- Optical path: 10 mm

- Spectral bandwidth: 6nm

- Number of Solvent: 1

- Certificate: GB/T 19001-2008/ISO 9001:2008

GC-MS, Q-Tek

- Automatic and manual calibration of GC-MS system, search by libraries, data processing, report generation

- SIM Wizard and Flex SIM productivity tools for quantitative analysis

- iDwell Time algorithm for SIM method parameters optimization

- GC has features proprietary design Electronic Pneumatic

- Control to maintain very stable flow to the MS detector during temperature programmed GC separation cycles offering excellent Retention.

GC-MSMS

- GC-MS/MS offers excellent anti-pollution capability, high stability, strong scalability, and exceptional cost-effectiveness.

- Ideal for applications in traditional Chinese medicine, agricultural residue detection, food safety, and environmental monitoring.

- Comes with advanced mass spectrometry workstation software for control and quantitative analysis.

- Software includes standard method library, intelligent batch processing, and customized report output, significantly reducing user operation difficulty.

- Features a rich application method library to fulfill the diverse needs of mass spectrometry users.

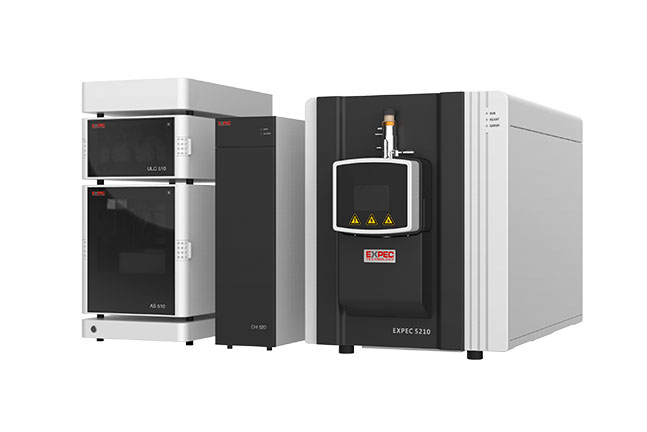

LC-MSMS/MS

- High sensitivity, stability, and scalability with strong cost performance.

- It is suitable for varied applications like environmental, medical, and food safety testing.

- Comes with a custom-developed software called Mass Expert for mass spectrometry control and analysis.

- The software includes features like automatic tuning, intelligent batch processing, and customizable report output, simplifying operations.

- Mass Expert is equipped with thousands of compound libraries and a rich set of application methods.

- Designed to meet diverse user needs and reduce complexity in mass spectrometry workflows.

Preparative HPLC, Inscinstech

- Binary high pressure gradient, binary low pressure gradient, quaternary low pressure gradient and isocratic pump are optional

- Configurable differential detector

- Dynamic mixers of various specifications, the mixing chamber can be changed quickly, suitable for different flow rate ranges

- Excellent flow rate accuracy, accuracy, component accuracy and gradient linearity

- Pressure fluctuation compensation technology can reduce system noise and improve the reproducibility of analysis results

- Dual beam compensation technology: high stability and low drift

GC7900 Gas Chromatograph

- Adopts AFC digital control technology, the automation level and overall performance are close to international first-line brands

- 7" industrial color LCD screen design, more complete display information, more reasonable interface operation

- Modular structure design. Variety of high-performance detectors are available, such as FID, TCD, ECD, FPD and NPD, etc., to meet the analysis needs of a variety of samples

- Adopts advanced 10/100M self-adaptive Ethernet communication interface, built-in IP protocol, easily form a local area network, realize long-distance transmission, remote control, remote diagnosis

ChromPlus4000 Gas Chromatograph

- Dual FID, TCD, NPD & ECD Detectors with four injectors to enhance analytical capabilities

- Thermodynamically designed oven accommodates capillary and packed columns

- Up to 5 individually controlled heated zones; up to 450°C for better method control

- Optional accessories such as Head Space Sampler, Auto Liquid Sampler, Methaniser and Auto Gas Sampling Valve

- Advanced Chromatography Software “CLARITY” from Data Apex

- Cost effective solution for QA/QC/Research applications

- Exceptionally compact size for better space utilisation

- PC control for all parameters

Carbon Sulphur Analyzer

- Sample Weight (Solid steel)

- Standard: 0.5g

- Accuracy C/S: 0.1 ppm

- Analysis Time: 25-60s adjustable (normally: 35s)

- Working Cycle: 24 hours

- Analysis range C: 0.0001 %-10.0000% (can be extended to 99.999%)

- Analysis range S: 0.0001 %-3.50000% (can be extended to 99.999%)

- Analysis Pool: 2

- Power consumption: 2.2KW

- Analysis Precision C : ≤RSD0.5%; S: RSD≤1.0%

Ion Chromatograph

- Built-in eluent generator, free from configuring eluent, with gradient elution available

- Built-in low-pressure degassing technology to eliminate bubble interference for stability

- Self-regenerating electrolytic micro-membrane suppressor, high pressure resistance, small dead volume, highly responsive to signals

- Modular design, convenient to assemble and disassemble , easy to operate

- Optional intelligent automatic injection system for large sample volumes, which features automatic dilution to save labor and time

- Work across a variety of detectors to expand the scope of applications of ion chromatography.

Ion Chromatograph CIC-D300+

- 10" HD touch screen: Real-time display of flow path and operation status of the instrument

- Built-in double membrane eluent generator: No need degassing pipe and capture column, has pressure resistance of 30MPa, simpler flow path and smaller dead volume.

- Ultra-pure ion purifier: It can purify water online and reduce the water requirements of the instrument, so as to reduce the baseline background and improve the signal-to-noise ratio.

- Suction sampling system: Uses peristaltic pump to suck samples to reduce cross pollution at the injection port.

- The gas-liquid separator removes most of bubbles entering the flow path, and the constant pressure and low pressure degasser continuously remove the residual gas dissolved in water.